At one time in this country, we made things like this. Today, manufacturing represents a smaller and smaller part of our economy.

The antics of Mitt Romney and Bain Capital were part of an overall larger trend that extended from 1980 until about today, but is fading out fast. These companies, and others, would make money killing off the last remnants of old rust-belt factories, often making money in the process. Today, few of these factories are left, and the opportunities for Venture Capitalists are getting more difficult and marginal.

There is little money to be made in "turning around" a modern company with modern factories, running at peak efficiency. You can't buy, groom, spin-off, re-sell, and shut down like in the good old days - the markets are getting better at valuating companies. And often, companies themselves are the ones who groom themselves for takeover, as in the case of Winn Dixie.

My Dad ran one such rust-belt factory - a small shop with mostly WW II-era equipment, that could not compete with other U.S. Companies, much less the Japanese and Germans. And today, the plant is closed, the people laid-off, and the buildings bulldozed to the ground. They threw around some grass-seed and a few ugly sculptures and called it an "art park" which sounded so much nicer than "Hazmat cleanup site."

But how did these companies come to fail? To understand this, you have to go back to before WW II, as events from that era started the trends that are finally sputtering to a halt, today.

Before World War II, we were a large manufacturing country, to be sure, but not as much of a powerhouse as we were in the postwar era. At the breakout of the war, our leaders were shocked to discover, for instance, that we had no domestic capacity for making instrument bearings. These are tiny ball bearings, that are the size of grains of sand. The outer race of such bearings is about the diameter of a pencil lead. These are used in the artificial horizons that, until fairly recently, were operated by gyros driven by engine vacuum. Each airplane needs one or more of these instruments, and as you can imagine, with thousands of warplanes coming off the assembly line, the need for such bearings was acute.

I worked for the company that made these bearings - New-Departure-Hyatt Bearings division of General Motors, located in Bristol, Connecticut. NDH, as it was called, was exemplary of what was called, in the 1930's, the Sloan vertical integration system - the expansion of a company to include all of the parts makers that supplied the parts to the cars. At GM we made every part for the car, except the tires, oil, and gasoline. But from sparkplugs, to batteries, to headlamps to wheel bearings, we made it all, pretty much. And this vertical-integration model worked - in the 1930's. In the postwar era, it would end up being GM's undoing, as well as Ford's and Chrysler's.

But thanks to the war effort, most manufacturers expanded rapidly, building new plants, hiring more workers, buying new machinery. At NDH, they started a crash program to start making these instrument bearings . And of course, they increased production of other types of bearings needed for aircraft, military vehicles, railroads, and whatever.

Incidentally, it was no coincidence that a bearing company would be located in Connecticut. Connecticut was the home of the inveterate Yankee Tinkerers - the clockmakers and inventors who built machines that were sold nationwide, in the 1800's. I had one such clock, made with wooden gears (until recently, when I realized that while an ugly old broken clock is cool to look at, having cash and one more thing not to own was even cooler). Mark Twain wrote a book about these sort of folks - A Connecticut Yankee in King Arthur's Court.

So, there you have it, at the beginning of the war, the Connecticut clock-makers squaring off against the Black Forest Cuckoo-Clock makers, the latter of which certainly had more technical expertise. Often, our ball-grinding equipment and other tools were in fact, German imports.

Rapid expansion due to the war meant that existing buildings were added on to, piecemeal, and new buildings thrown up, in short order. Many of these buildings followed pre-war design themes, and had multiple stories and were not very large in scale. When the war ended, the resulting buildings were scattered across acres of land, an indeed across several towns. It was not atypical for a factory then to comprise of a number of discrete buildings, often located miles apart. The inefficiencies of transporting materials across town by truck are self-evident.

In Germany and Japan, the factories were bombed flat, and they started over - with new factory designs and new, more efficient machinery. They also started anew with a workforce that was desperate to make a few nickels to buy food. The single-floor factory plan, in a single building, was more efficient and less costly than the old brick multi-story factories of the past. The Germans and Japanese entered the 1950's with a good foundation for future competition.

We had no war to level our plants - that would take decades more. In the late 1960's, GM decided to modernize the NDH plant and abandon all the old 1920's-era structures and build one new, single-level 22-acre building outside of town, where land was cheap and the rail line and trucks would have easy access. Having a factory "downtown" no longer made sense - there was no need to be near water power, and workers now drove to work, instead of walking to the plant gates with their lunch pails in hand.

22 acres under one roof - it was an enormous building. But inside was largely the same old equipment from the original factory. Some machinery I worked on there had tags riveted to them saying, "This is a WAR machine, built to WAR standards" - whatever that meant (usually, the ornate finishes of the machinery of the past was omitted). The plant never made money for GM, and likely never paid back its investment. And if you multiply this mistake by all the parts suppliers for GM - Delco, Guide Lamp, AC, Frigidaire, Fisher Body, etc. - it comes out to a lot of money.

Meanwhile, the Japanese started entering our market - using an industrial model radically different than our own. Instead of vertical-integration, they used a Keritsu system of captive parts suppliers, each profitable in its own right. Japan's parts suppliers were not loss-leaders, but profit makers. They did not drag down the parent company, because they simply were not part of the parent company.

The Japanese also developed an efficient system of "just in time" inventory - supplying parts as they were needed, and not a moment before or after. In the U.S., we made warehouses of parts, stored them, and then pulled them from the shelves and shipped them, upon request. As a result, we incurred not only the huge warehousing and labor costs, but also had to run expensive inventory controls and actually pay taxes on inventory (at least in Connecticut). And boy-howdy, did we have inventory!

The American factory system was antiquated, dated, obsolete, inefficient, and ready for an overhaul. But in the prosperity of post-war America, no one wanted to rock the boat. The unions demanded steep wage increases - and management placated them with empty promises of future benefits that were severely underfunded - pension plans, medical plans, and the like. The cost of doing business increased, but still, many companies remained profitable. No one could see any reason to restructure the business system at the time - why bother bailing out your boat, when there is only a "little" water in the bilge and you are still making headway?

But the cancer that would kill off these industries had metastasized, and it was only a matter of time - a decade or two, before these companies started dropping like flies. My Dad's plant - which made truck parts - closed in the early 1980's. The factory I worked in - NDH Bristol - followed suit shortly thereafter. 22 acres of factory - over 8,000 employees - all reduced to little more than a warehouse. And at the time, many workers said, "They will never close this place! GM is too big to fail!"

And yet, while they were saying this, a large flatbed rail car sat on the siding next to the forge plant, while workers pulled another 7" upsetter out of the ground - an enormous forging machine with a 22-foot diameter flywheel that smashed railroad bearing rings out of bars of white-hot steel the size of telephone poles. The machines were twice as wide as the rail cars they sat on, and special clearances needed to be obtained to get them from the plant down to the sea - where they would be loaded onto cargo ships (likely older Liberty or Victory ships, built for the war, in another layer of irony) to be shipped to their new owners in India.

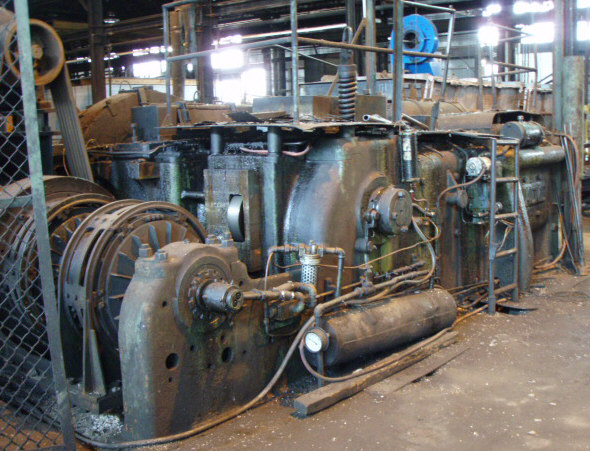

A 5-inch upsetter. Most of the machine is not visible, as it sits in a 'pit' below ground.

"Oh, sure," one worker said, "They're selling off the forging business and shipping it all to India. But that was a money-loser. The rest of the plant will stay intact!"

But one of my classmates at GMI submitted, as his Senior Thesis, a plan to outsource ball production, so that we would only make rings and then assemble the bearings. Not only did he get an "A" in his thesis, the plan was approved and, soon, our German-made ball machines were offered for auction and then shipped out as well.

A ball-grinding machine, now made in India.

(Ball-grinding, by the way, is a messy business. Water/Oil based lubricants are used to grind the balls, and a fine mixture of metals ends up in this grinding fluid. Recycling or disposing of this fluid is often problematic and expensive. And it is highly flammable. Shortly after GM built the new 22-acre factory, a grinding fluid fire started, at an intense heat caused by the fine particulate metals, and burned one-quarter of the new factory down.)

I said to my classmate, "If your thesis is correct, and buying Japanese and German balls is cheaper than making our own, them why not just buy the inner and outer rings from them as well? And the cages? Why not cut to the chase and simply buy the whole assembled bearing from them?"

He just smiled and said, "You're getting the idea."

I started to realize that a career in that plant would be one of unwinding it, not building it up. Due to the Union contract, it would be hard to close the plant in one fell swoop. But doing it piecemeal, that could work. And eventually, the whole plant was shuttered, pretty much in this fashion, as GM could no longer afford to be making things other than cars, or even the car parts.

Now repeat this scenario thousands and thousands of times across the land and you can start to understand what happened to American Manufacturing in the last few decades. Old and obsolete plants, high labor cost structures, and tough competition from overseas meant that many of these old businesses were headed to the scrapyard in short order.

Enter the Vulture Capitalist. While these plants were old and obsolete, the labor contracts uncompetitive, the pensions underfunded, there were still ways to make money taking these places apart - legally, illegally, morally or immorally. As I noted in my earlier post, a lot of people can make money by busting out a business - it is not exactly legal or moral. But there are legal ways as well - perhaps not moral, but that is your judgement to make.

For example, you buy an old rustbelt company that has a bleak future. The equipment is old and obsolete, the workforce is older and has high health care costs. The pension plan is underfunded. Maybe the company is breaking even, running at a small loss, or whatever. The owners unload it onto you with a sigh of relief, and take the money and move to Florida, to sit in the sand and no longer have nightmares about HazMat cleanups, Union Strikes, and the underfunded pension plan. It no longer is their problem.

The new owners quickly take charge and the first thing they do is spin-off any divisions that might be profitable. As a part of a money-losing company, such divisions are propping up the older, cash-hemorrhaging divisions. But as stand-alones, they could be profitable enterprises. So you sell off Frigidaire, Terex, Electromotive, EDS, and other "non-core" businesses, and then pocket the cash. Suddenly, the company is showing a huge profit - a one-time profit, but nevertheless a profit. As the new owner of the company, you put a lot of that in your pocket. Or as the manager of the Capital company investing in it, you collect millions in fees.

What about the core business? Well, you go in and slash costs - eliminate maintenance. Eliminate buying new machinery. Take a time-honored design and gut the content until it is so cheaply made that no one would want it. But it will take market a few years to figure this out - and people will continue to pay top price for the product, assuming it had the same quality as in years past. It is like what AMF did, when it bought Harley-Davidson.

So, again, you show a short-term profit, and you make a ton of money, but it not only is a one-time deal, it is the death-knell for the company. You rake in a lot of dough, in the short-term, but the customers are screwed by substandard products and the workers are screwed by the fact the plant will be closing sooner than expected.

Sooner than expected - and that is the key. Again, these sorts of factories are riddled with cancer - they are going to die anyway, or at least that is the logic. It would be like if your Mom had cancer and you sold her Oxycontin on the street for $20 a pill. She's going to die anyway, so you might as well make a little money from it, right? And as odious as that sounds, that did indeed happen to a friend of mine. Her son could have had a fine career at Bain Capital.

So, now, the company is stripped down to its bare essentials. The factory is in bad shape, not a nickel has been put into maintenance or improvements (Sort of like Sears) but gee, these old factories take a long time to kill, don't they? And in the interim, some jackass small investors are buying your stock, after seeing the stellar profit picture for the last two years. They figure that you must have some grand plan of rebuilding the place and making money, but you are in fact just the undertaker pulling all the gold teeth out of the corpse.

God, I love a good metaphor!

So you can make even more money manipulating the stock price this way, unless of course, you took the company private. But either way, there is still money to be made, flogging the corpse. You run up debt to suppliers while still selling product. Since you are not paying your suppliers, your ordinarily money-losing company appears profitable. Maybe you go to the debt market and load up the company with debt, thus showing more short-term profits but creating more long-term problems. Shame on the folks willing to loan you that money, but most of them are "institutional investors" and are clueless as to what you are up to.

And of course, you stopped funding the pension plan ages ago. While it was underfunded when you bought the place, it is really screwed now. And yet, your hourly workers spend their lunch hours dreaming of their Florida retirement homes and how much they will get from their pensions. Some have already retired and situated themselves in scenarios that require a steady cash-flow from the pension plan to pay for their retirement homes and leased cars. Boy, are they in for a rude awakening! You have a good chuckle every time you think about it.

And perhaps this is the one area where there is some questions about legality and certainly morality. Is it legal to intentionally 'gut' a company while underfunding the pension plan? Is it moral? Should people promise lavish pensions to workers when they have no real intention of paying them later on?

Of course, the point may be moot today - Defined Benefit Pension Plans are largely a thing of the past. It is hard to 'underfund' a 401(k) plan without someone noticing it. But it is one good reason why, when you leave a job, you should roll-over your 401(k) to an IRA.

When the company is finally leveraged to the hilt - up to its eyeballs in debt, and suppliers no longer willing to ship parts without cash-in-hand, you close the place down. Maybe you get lucky and the union stupidly decides to go out on strike - they still have no clue what you are up to, do they? You laugh at their naivete with your friends at the Country Club. Stupid Unions!

So, off to bankruptcy court you go, and the Judge looks at the mess you've made of the books and realizes there is no "there" there - they cannot reorganize this place and make money under any circumstances. So they liquidate the place - or try to . No one wants to buy the run-down factory and its HazMat liabilities. So it sits abandoned. What little machinery that is of any value is sold off. Much of it is sold as scrap metal, to be cut up and shipped to China to be made into products to be sold back to America.

The workers are sent home to collect unemployment and perhaps try early retirement. But since the company is bankrupt, the Pension Benefit Guaranty Corporation - a government agency - has taken over the tattered remnants of the pension plan, and doles out what little is left of the pie to the retirees - often less than half of what they were expecting. "Make the pie bigger," some Republicans like to say - but not in this instance.

So, another rust-belt factory is closed. And the suppliers to that factory take huge hits, not only in unpaid invoices, but in the loss of a good customer. The town the factory is located in will struggle until it finds a new "anchor". Bristol, Connecticut found ESPN (or vice-versa) in a classic move from a manufacturing-based to an information-based economy. But many other towns and cities, like Flint Michigan, never recover, and people move away, stores close, and pretty soon, the entire town is pretty much abandoned and full of welfare recipients. The overall cost to us all, is fairly high, as our tax dollars end up subsidizing these folks. And if you lived in such a town, you lose what little equity you had in your home or business.

Now to be fair, as I noted earlier, these rust-belt factories were destined to fail. They are the sick and lame gazelles in the herd, and the predators - the leopards, cheetahs, lions, take them down and feast on the remains. Is this a bad thing? The gazelle would have died anyway, and simply rotted in the sun.

Could these rust-belt factories have been saved? Maybe. The fact that new factories have been built in this country - often by our foreign competitors - and thrive, is an indication that manufacturing is not, in fact, dead. And the recent growth in manufacturing and manufacturing hiring in this country is one sign that perhaps we have reached a nadir point and are poised to recover.

A new economy with a cheaper labor force - and a heavier use of automation and robotics - will be more efficient and profitable. Millions of people left the family farm in the 1800's and 1900's and sought manufacturing jobs in the cities, as farming required fewer and fewer man-hours of labor, particularly once the tractor was invented. Today's mega-tractors can plow and harvest acres of land in a small fraction of the time required to do so by horse-drawn plow.

Similarly, today's factories require far fewer laborers to run machines - but more trained mechanics to repair, program, and maintain the machines. The labor contracts of old - which often stipulated the number of workers in a plant - were a death sentence to many factories, as they negated any savings due to automation and strangled the capital necessary to invest in automation.

So, economically, one could make the argument that the Bain Capitals of the world, like the Lions of the Serengeti, or the Sharks of the reef, are scavengers who clean up the ecosystem, by culling the weak, diseased, and dying, from the herd, pack, or school. And while this may make economic sense, it is little comfort to the gazelle being disemboweled while still alive.

Could any of these old rust-belt factories been saved? Perhaps, but it would have taken a vision and fortitude that were largely lacking in the 1950's and 1960's. A factory is a place where everyone - from worker, to management, to shareholder, to supplier, to customer, to debt-holder, to even the local tax collector - hopes to take money or value from. And usually, given our human nature, none of us is willing to make sacrifices on our own, unless catastrophic circumstances are about to occur (sort of sounds like our budget and debt crises, no?). It is catastrophe theory in real-life, driven by our human needs.

A far-sighted management and union leadership could have seen the eventual scenario coming down and chosen, instead of short-term gains in terms of salaries and benefits, to invest in new manufacturing plants and more rational labor contracts and management pay. And perhaps, in a profit-sharing plan, all could have profited more in the long run. But in the short run, the plant across the street, which is playing the race-to-the-bottom, is paying more, so you can expect to lose your top talent to them.

So, perhaps all of this was inevitable. And you can "blame" a Vulture Capitalist for picking at a company's corpse, or view it as an inevitable part of the food chain. Either way, the companies involved would still not be with us, today.

I guess it wouldn't be so bad if they didn't appear to be enjoying it so much...

UPDATE: This link describes how one VC firm bought the Friendly's restaurant chain, drove it into bankruptcy, spun off the pension liability to the PBGC, and then took back the chain, now stripped of pension liability, that they can then build back up and re-sell at a profit. Neat, eh?